Lets bring this thread back to ******** on harley:

Question:

Why do all the chicks who ride harleys look like bartenders from 1982?

You mean like this...

Sorry... LOL

Lets bring this thread back to ******** on harley:

Question:

Why do all the chicks who ride harleys look like bartenders from 1982?

How about 11,000 HP @ 9,500 rpm ? 20 Facts About Top Fuel Drag Racing Cars You Need To Know (thethings.com)Near perfect for a slow rolling engine.

17,500rpm, not so much.

I like this one way better:How about 11,000 HP @ 9,500 rpm ? 20 Facts About Top Fuel Drag Racing Cars You Need To Know (thethings.com)

A couple of things they didn't tell us that I find amazingHow about 11,000 HP @ 9,500 rpm ? 20 Facts About Top Fuel Drag Racing Cars You Need To Know (thethings.com)

How about 11,000 HP @ 9,500 rpm ? 20 Facts About Top Fuel Drag Racing Cars You Need To Know (thethings.com)

Eeek. Grabbing the hub of a spinning prop to stall out the 260cc engine would not have been my first choice.the kind of engines H-D should be building by now.

Years ago I saw a great great documentary that explored a few Harley design changes. Turns out chain driven cams and belt driven wheels were adopted mostly to reduce mechanical noise. Same to some degree for rubber mounting engines engine. Belt driven wheels and chain driven cams are costlier in production so it's not a cost thing.Totally for the purpose of building an engine more cheaply.

Ever tried to push a motorcycle with a belt final drive, they don't push easy.

H-D puts a belt final drive on their production bikes, totally for the purpose of building a motorcycle more cheaply.

& don't be telling me H-D cares about the less vibration, it's just selling the only sales advantage of a belt final drive. If H-D was actually designing and building highly engineered product their motorcycles would have shaft drive.

lol or electric by now.

Last summer I saw a Sportster that had such a badly worn out primary chain that it had started to saw its way through the shifter shaft. At the same time, the clutch basket (which houses the alternator on the backside) had walked around enough to tear out the windings so it wasn't charging. Admittedly it was an older machine, but stuff like this apparently happens all too often.One of the highest fail parts on a Harley engine is the primary chain tensioner and the torque compensator*

*(a torque cushion which is only required because their silly engine design has 2 lop-sided cylinders out of the 7 it would take to make it run smooth)

From what I read it happens to all of them.Last summer I saw a Sportster that had such a badly worn out primary chain that it had started to saw its way through the shifter shaft. At the same time, the clutch basket (which houses the alternator on the backside) had walked around enough to tear out the windings so it wasn't charging. Admittedly it was an older machine, but stuff like this apparently happens all too often.

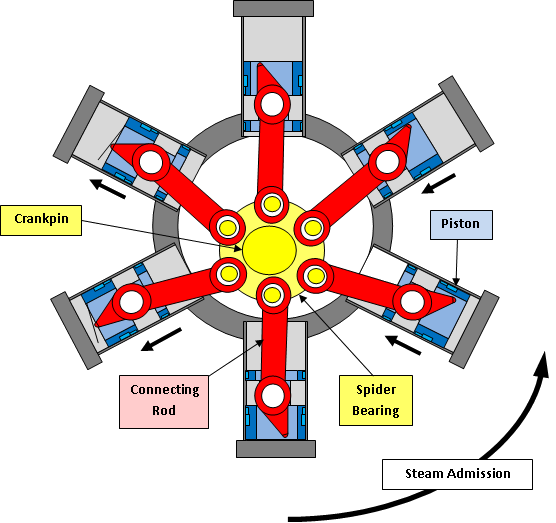

The conrods are attached to something that looks like a flower so they are all in one plane. Not sure what the proper name is.Radial engines : How do they get all those con rods on such a short crankshaft? Or do they not all run on the same shaft?

Packaging and cooling a radial engine in a bike are problems not easily solved. In wheel radial can work but your unsprung weight is ugly.brilliant eh

and the silly thing it was the radial engine that inspired them to make the 45 V-twin, and in all those years following H-D never got around to adding the rest of the cylinders,possibly because it would have addressed the vibration, torque variations and moderate performance issues.

They can also have a "master rod"Radial engines : How do they get all those con rods on such a short crankshaft? Or do they not all run on the same shaft?

I learned a lot about British engineering a long time ago. First by working on MGs, Triumphs and Jags, and later at a British electronics plant..... yeah I'm working on a Commando.... trying to sort out the suspension... POS... what a stupid setup.