Mad Mike

Well-known member

They are underway. Look behind the boats -- forward motion levels the chop in their wake.That just adds confusion to what is already a crap show. If they're anchored, why running lights? If they're moving, why zero wake?

They are underway. Look behind the boats -- forward motion levels the chop in their wake.That just adds confusion to what is already a crap show. If they're anchored, why running lights? If they're moving, why zero wake?

Check the colours of the running lights.They are underway. Look behind the boats -- forward motion levels the chop in their wake.

I recarpeted my boat when I got it. Cost me a couple hundred and a day. It's held up well. Iirc I glued it down with spray contact cement. Thankfully the wood was OK and I didn't need to replace it.Where would one find a good deal on some marine plywood. Or is that even necessary in my case?

I am wanting to redo the flooring and other paneling of my boat and redo the carpeting on it. The current plywood is PT but im thinking marine grade will be better. Mind you, this plywood is probably 20 years old. Some section have become soft to step on and the carpet is worn out.

This is a custom made job by the PO (family friend). All secured with stainless steel nut/bolt and screws where necessary. The easy part is that there is no guess work on measurements as I can trace the exiting panels and cut. The hard part will be removing the nuts/bolts cause all the ends of the bolt thread had been scored to prevent the nuts from unscrewing.

paging @crankcall

View attachment 69211

The current carpet is wrapped around the existing panels so they need to be removed for recarpeting.I recarpeted my boat when I got it. Cost me a couple hundred and a day. It's held up well. Iirc I glued it down with spray contact cement. Thankfully the wood was OK and I didn't need to replace it.

I use exterior grade ply when repairing wood in boats - Home Depot 5/8 for floors, 3/4 for seats tops and foredeck.The current carpet is wrapped around the existing panels so they need to be removed for recarpeting.

I found a deal in a marine grade carpet for $100. 6 x 23. I think that's a decent deal.

I use exterior grade ply when repairing wood in boats - Home Depot 5/8 for floors, 3/4 for seats tops and foredeck.

I always paint the repair panels with epoxy floor paint, sides and edges. You can use the cheap stuff designed for concrete garage floors.

When tracing old panels, just cut the carpet back 1” on each edge (save time). I like polyolefin outdoor carpet from Home Depot. Good price, and goes down with outdoor carpet glue.

I change fasteners to the ones used on pontoon boats. Way better than nuts and bolts. https://www.amazon.ca/Stainless-Sel...c5ead2c4602e399b8181e465cf747605&gad_source=4

For the nut and bolt hinges, use regular stainless and nylock nuts. Don’t bother peen or score stainless - they will break or strip heads before coming loose. I’d just use a zip cut wheel and a grinder to cut the loose on the underside.

I was thinking of using the 3/4 on the main floor and the upper deck where there is standing room. And maybe the 5/8 for the side walls and all other hatches etc.Just consider if your putting a stainless fastener into an aluminum boat , go buy a tub of Tef-gel . Permatex corrosion antiseize also works but that crap gets all over everything.

The manufacturer does not use it when making boats , because in the 5 yr warranty they will never have to F with that fastener again. But you might .

Sent from my iPhone using GTAMotorcycle.com

I think most small boats use 5/8" on the main floor. It's lighter and there are lots of support points I the main floor. 3/4" is used for hatch covers and foredecks as there is limited support, There are no rules so you can do what works.I was thinking of using the 3/4 on the main floor and the upper deck where there is standing room. And maybe the 5/8 for the side walls and all other hatches etc.

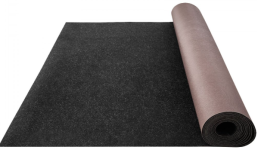

As for carpet I was thinking of using the Vevor marine carpet. Looks like it has a rubber backing that should be easy to glue onto the wood.

View attachment 69243

I may also consider the foam flooring for the main floor area just for esthetics. But they come in a max width of 48 inches and I need just slightly over 5 ft. I wouldn't like to join to sections but I may have to if I got this way.

View attachment 69242

Any opinions on this foam flooring stuff.

The existing panels are fastened to aluminum angle corners with nut and bolt where both sides are accessible. Most nuts are just plain nuts with the bolts cut to just past the nut and the last thread scored or hammered. This will make things difficult for removal and reuse of bolts, possibly damaging both and may not be reused. There are some nylon nuts.

I like the self tapping screws MM suggested but I feel like they may be an issue in areas where the back side is accessible and where hands will be looking for things and may get scratched by the tip.

I would like to reuse the exiting bolts but it may not be worth the hassle to repair the thread and trying to match up the length in the area being used.

I think I will just order a bunch of new bolts/scresws.

Lots to think about for this winter project but knowing me I will get busy with other stuff and this will get put on the back burner.

I have heard from bass boat friends that the foam degrades after 8 years or so. That is mostly in full sun though. If you are covering the boat it shpuld also longer. From similar foam on paddleboards, it will get dirty and marked up. If ypu have ocd, carpet will look new for longer.I was thinking of using the 3/4 on the main floor and the upper deck where there is standing room. And maybe the 5/8 for the side walls and all other hatches etc.

As for carpet I was thinking of using the Vevor marine carpet. Looks like it has a rubber backing that should be easy to glue onto the wood.

View attachment 69243

I may also consider the foam flooring for the main floor area just for esthetics. But they come in a max width of 48 inches and I need just slightly over 5 ft. I wouldn't like to join to sections but I may have to if I got this way.

View attachment 69242

Any opinions on this foam flooring stuff.

The existing panels are fastened to aluminum angle corners with nut and bolt where both sides are accessible. Most nuts are just plain nuts with the bolts cut to just past the nut and the last thread scored or hammered. This will make things difficult for removal and reuse of bolts, possibly damaging both and may not be reused. There are some nylon nuts.

I like the self tapping screws MM suggested but I feel like they may be an issue in areas where the back side is accessible and where hands will be looking for things and may get scratched by the tip.

I would like to reuse the exiting bolts but it may not be worth the hassle to repair the thread and trying to match up the length in the area being used.

I think I will just order a bunch of new bolts/scresws.

Lots to think about for this winter project but knowing me I will get busy with other stuff and this will get put on the back burner.

I think most small boats use 5/8" on the main floor. It's lighter and there are lots of support points I the main floor. 3/4" is used for hatch covers and foredecks as there is limited support, There are no rules so you can do what works.

The EVA foam is nice looking, I've never used it. The rubber-backed outdoor carpet is great if it's being held in place with snaps (like on a flybridge or rear deck of a cruiser), I wouldn't use it for glue down in a fishing boat. Rubber backing will eventually separate from the carpet then you get stretches and wrinkles - looks horrible. Use polyolefin outdoor carpet that has no laminated backing.

I have heard from bass boat friends that the foam degrades after 8 years or so. That is mostly in full sun though. If you are covering the boat it shpuld also longer. From similar foam on paddleboards, it will get dirty and marked up. If ypu have ocd, carpet will look new for longer.

Any comments on the plywood the devlopers use to post proposed zoning changes? Stuff seems to last forever, zero maintenance. Thicknesses may be limited to half inch, 12 mm and something in between.So plywood time, actual marine grade ply has no interior core void ( missing knots) so it’s structural and won’t come apart. PT and exterior sheathing grade ply is made with the same phenolic glue and it’s water proof . The things is sheathing ply and PT is often a bit bowed but screws and bolts fixes that . Marine ply is often mohogany / sapelle or fir so it’s pretty flat , but you don’t actual need it for what you’re doing . Home Depot exterior ply will work for the next 20 yrs .

There are no good deals on actual marine ply , Noah’s in Mississauga has it , exotic in Burlington or Woodshed in Smithville, but they are all $200 a panel.

McFadden in Oakville west should have it , still $200 a panel

Sent from my iPhone using GTAMotorcycle.com

The styrofoam should be enough to keep the boat at the surface. If you have no foam and you happen to fill it with water, it becomes a submarine. With environmental protection laws, you need to recover the boat. On the surface, that is a tow or a buddy with a boat. As a submarine, that means you need a diver (or ROV if deep) and a barge/boat with a winch and davit.Question for the boat experts.

I was was thinking about the configuration of my boat and possibly reconfiguring IF I was to redo the plywood and carpet.

As you see in the picture, the current boat has the typical benches that you find in a aluminum shell boat. At the back of the boat and under the front deck where the front pedestal base is located. The inside of the benches is filled with styrofoam. I am not sure if this was a factory design (the styrofoam part) or if the previous owner filled the benches himself. Would removing the bench and more specifically eliminating the styrofoam have any negative effect on the boat?

I am guessing the styrofoam is there to provide more buoyancy in the even of a tip over. But I doubt that it would actually prevent the boat from sinking.

View attachment 69365

.Question for the boat experts.

I was was thinking about the configuration of my boat and possibly reconfiguring IF I was to redo the plywood and carpet.

As you see in the picture, the current boat has the typical benches that you find in a aluminum shell boat. At the back of the boat and under the front deck where the front pedestal base is located. The inside of the benches is filled with styrofoam. I am not sure if this was a factory design (the styrofoam part) or if the previous owner filled the benches himself. Would removing the bench and more specifically eliminating the styrofoam have any negative effect on the boat?

I am guessing the styrofoam is there to provide more buoyancy in the even of a tip over. But I doubt that it would actually prevent the boat from sinking.

View attachment 69365