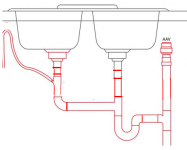

You can buy a double sink connection that includes everything wo connect 2 sinks and a dishwasher - OR make one from ABS parts.

View attachment 64702

You need more as you must plumb in a vent, trap, (optional dishwasher) and connect to the 1-1/2" ABS drain running thru th e floor.

View attachment 64707

Bill of materials (mumbers in brackets are if you buy the kit)

All plumbing should be 1.5" ABS

6' ABS (4')

2x ABS straine rconnectors (0), connects to sink strainer downspouts

View attachment 64708

2x sanitary tee (1), one connects the 2 downspouts to the drain line, the other connects to the vent line. OPTIONAL Dishwasher hookup tee.

View attachment 64704

1 Trap (suggest using a union type with ball connection - best for novice plumbers)

View attachment 64703

2x 90 degree elbows (1) to connect trap to main line and connect cross pipe

View attachment 64709

1x Air admittance valve (this allows air into the drain when water is leaving.

View attachment 64705

Small bottle of ABS cement.