What the heck are the magnets for?Magnets corrode on my delta kitchen faucet. On the upside, they come with a tool and apparently lifetime free magnets. Last change broke the tool and used up my last magnet. Hopefully getting them to send me more wont be an issue (previous owner bought the faucet so I dont know when or where).

Enough of COVID...what are you doing to the house?

- Thread starter mimico_polak

- Start date

Mad Mike

Well-known member

My last faucet rusted in after 2 years. While trying to free the nut I cracked the granite/resin sink. Ended up cutting the thing out with a zip wheel. The sparks from the zip wheel pitted the subway tiles in my backslash.Magnets corrode on my delta kitchen faucet. On the upside, they come with a tool and apparently lifetime free magnets. Last change broke the tool and used up my last magnet. Hopefully getting them to send me more wont be an issue (previous owner bought the faucet so I dont know when or where).

A $200 1hr job ended up costing $1000 and a day.

Integral sprayer on gooseneck. Ring magnet holds in in place when you arent using the hose.What the heck are the magnets for?

This has a weight too. Magnet just gives a satisfying click and avoids a cock-assed nozzle.I like the donut weight on the sprayer hose. KIS.

On an unrelated note, figured out why a heated floor was being flaky. On the upside, the floor wire tests OK. Crap electrical install as expected with conductors stripped too far and left exposed. Controller uses two omron relays to control each leg. It can be used on 120 or 240. Mine is wired for 120 and the relay controlling the neutral leg is dodgy. It clicks fine but some of the time it gives a good connection and some of the time it gives no connection. Options are bodge wire around that relay because it is neutral, replace relay (need to desolder all wires in and out of board and then replace relay) or replace whole controller. Reassembled for now mostly as found but fixed exposed conductor issue.

Edit:

Not going to hardwire the neutral. On the off-chance the hot relay sticks, I'm not sure if the controller has a backup plan to prevent runaway floor temp. It has built in gfci with a manual test button but I dont know if it has a way to trip itself in an emergency.

Last edited:

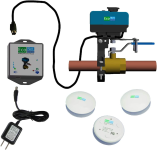

Conceptually, I like the idea of Phyn or Flo. They monitor water flow and shut off if something is fishy (and both can also have traditional water sensors for the floor). A small leak somewhere (even in the toilet) can cost me a lot of money in water so they can actually save me some money to help pay for them. With conventional sensors, if the leak is in a wall, there is no guarantee that is trips a sensor before damage is castastrophic. Once I'm already in an insurance claim, I don't really care if it's 30K or 300K. I dislike the cloud stupidity of Phyn/Flo and how often smart devices get abandoned and become useless. Moen owns Flo so does that make it more or less likely to get the axe?Anyone have experience with econet bulldog leak detection shutoff? I would prefer to source a normally closed solenoid valve and hard wire it to leak sensors throughout the house, but have been told I have a tendency to get neurotic.

View attachment 58632

As a first step, I would call your insurance company and see if they have any requirements/approved systems to get a discount. You are mitigating their risk with your money so there should be something.

Relax

Well-known member

Conceptually, I like the idea of Phyn or Flo. They monitor water flow and shut off if something is fishy (and both can also have traditional water sensors for the floor). A small leak somewhere (even in the toilet) can cost me a lot of money in water so they can actually save me some money to help pay for them. With conventional sensors, if the leak is in a wall, there is no guarantee that is trips a sensor before damage is castastrophic. Once I'm already in an insurance claim, I don't really care if it's 30K or 300K. I dislike the cloud stupidity of Phyn/Flo and how often smart devices get abandoned and become useless. Moen owns Flo so does that make it more or less likely to get the axe?

As a first step, I would call your insurance company and see if they have any requirements/approved systems to get a discount. You are mitigating their risk with your money so there should be something.

I'd also be worried about how much torque the motor/mount can generate. I have the same quarter-turn ball-valve shutoffs on my tankless heater and they're a bear to turn, but probably because they've only been used once or twice in the last 13 years.

I would hope the 1/4 turn one he posted a picture of exercised the valve every week or so. Just a quick on/off. An automatic system that is never tested is worse than nothing as you rely on it and it probably wont work.I'd also be worried about how much torque the motor/mount can generate. I have the same quarter-turn ball-valve shutoffs on my tankless heater and they're a bear to turn, but probably because they've only been used once or twice in the last 13 years.

daught

Well-known member

My valve is fairly easy to operate, but the torque is a valid concern.

The Flo is all cloud and phone apps. It has many pictures of the phone, and pretty water consumption graphs, but no mention of it is a motorized valve or a normally closed selenoid. Small leak monitoring does not provide much value to me as I have flat rate water. I can see if my toilet leaks. Anyways thanks, it might be a great product, I will have to sit down and look further in to it.

I did find a source for exactly the valve type I am looking for. https://www.automationdirect.com/ad.../thermoplastic_solenoid_valves/ns211yf02cpeg5 . The sensors are very common.

The Flo is all cloud and phone apps. It has many pictures of the phone, and pretty water consumption graphs, but no mention of it is a motorized valve or a normally closed selenoid. Small leak monitoring does not provide much value to me as I have flat rate water. I can see if my toilet leaks. Anyways thanks, it might be a great product, I will have to sit down and look further in to it.

I did find a source for exactly the valve type I am looking for. https://www.automationdirect.com/ad.../thermoplastic_solenoid_valves/ns211yf02cpeg5 . The sensors are very common.

Keep in mind, if you use a normally closed solenoid and dont have backup power, a power outage also disables your water.My valve is fairly easy to operate, but the torque is a valid concern.

The Flo is all cloud and phone apps. It has many pictures of the phone, and pretty water consumption graphs, but no mention of it is a motorized valve or a normally closed selenoid. Small leak monitoring does not provide much value to me as I have flat rate water. I can see if my toilet leaks. Anyways thanks, it might be a great product, I will have to sit down and look further in to it.

I did find a source for exactly the valve type I am looking for. https://www.automationdirect.com/ad.../thermoplastic_solenoid_valves/ns211yf02cpeg5 . The sensors are very common.

In that note, is there a way to tie in the water heater so it gets cut at the same time as the water if a leak is detected? I dont love the idea of a water heater in a leaky plumbing system with no access to fill water. Sure, there may be a high limit safety but again, it's not routinely tested so I dont trust it.

daught

Well-known member

Yep, a battery backup or manual bypass should be installed.Keep in mind, if you use a normally closed solenoid and dont have backup power, a power outage also disables your water.

In that note, is there a way to tie in the water heater so it gets cut at the same time as the water if a leak is detected? I dont love the idea of a water heater in a leaky plumbing system with no access to fill water. Sure, there may be a high limit safety but again, it's not routinely tested so I dont trust it.

Yes, there are systems that do exactly that. They have a water sensor, a water supply solenoid valve, and a contactor that cuts power to the tank.

I found my sensors. BAPI manufactures sensors with normally open held closed contacts. Basically, if water is detected or there is any trouble in the system, the water valve closes. Usually these are $200+, but I stumbled over a bunch of them on ebay for $35. I would have preferred a rope sensor, but at $35, I can't complain.

The problem with the Moen and just about everything that comes with a coiled up plastic hose is that the hose takes a set during packaging and shipping and ties itself into a knot under the sink. Because of the special fittings one can't upgrade to a better hose.That was my last Moen install. Snap Snap Click Click done. Great design. Very happy with it.

(offsets the POS Artika sink fiasco)

I know a bit about the cables but every controller is different. If a cable fails and there is no ground fault protection the cable can fry itself, going from a repairable situation to total replacement.This has a weight too. Magnet just gives a satisfying click and avoids a cock-assed nozzle.

On an unrelated note, figured out why a heated floor was being flaky. On the upside, the floor wire tests OK. Crap electrical install as expected with conductors stripped too far and left exposed. Controller uses two omron relays to control each leg. It can be used on 120 or 240. Mine is wired for 120 and the relay controlling the neutral leg is dodgy. It clicks fine but some of the time it gives a good connection and some of the time it gives no connection. Options are bodge wire around that relay because it is neutral, replace relay (need to desolder all wires in and out of board and then replace relay) or replace whole controller. Reassembled for now mostly as found but fixed exposed conductor issue.

Edit:

Not going to hardwire the neutral. On the off-chance the hot relay sticks, I'm not sure if the controller has a backup plan to prevent runaway floor temp. It has built in gfci with a manual test button but I dont know if it has a way to trip itself in an emergency.

Most modern controllers have an upper limit of 104°F but a bad installation can go ballistic. An old gent died of burns a few years back due to a combination of errors. Niagara On The Lake. I assume he got a hotfoot and lost his balance. He died of his burns a few days later. I calculated a floor temperature of 170°F.

I got similar but lesser burns on my calf from working on my black roof in August but I was wearing jeans, not barefoot.

Most of the super strong compact magnets are neodymium and they rust unless plated. Alnico doesn't rust but they aren't as powerful or compact.Integral sprayer on gooseneck. Ring magnet holds in in place when you arent using the hose.

This is a Nuheat Home. 494 feet of cable,I know a bit about the cables but every controller is different. If a cable fails and there is no ground fault protection the cable can fry itself, going from a repairable situation to total replacement.

Most modern controllers have an upper limit of 104°F but a bad installation can go ballistic. An old gent died of burns a few years back due to a combination of errors. Niagara On The Lake. I assume he got a hotfoot and lost his balance. He died of his burns a few days later. I calculated a floor temperature of 170°F.

I got similar but lesser burns on my calf from working on my black roof in August but I was wearing jeans, not barefoot.

Last edited:

They are encased Neodymium ring magnets but the plastic casing gives up after a thousands of impacts and lets moisture in. Old magnet was at least three years old. Old ring magnet helped me grab fish tape for thermostat project.Most of the super strong compact magnets are neodymium and they rust unless plated. Alnico doesn't rust but they aren't as powerful or compact.

I got a free Nuheat cable for my daughter when I was servicing their product. I had to buy the thermostat and the distributor praised Nuheat for their deliveries and service.This is a Nuheat Home. 494 feet of cable, 12.2 kW @ 120V. Marked and tested at 9.9 ohms. I didn't run an insulation test on it as problem was identified in the controller and I need to read up on heat cable before I whack it with high voltage. Buying a premanufactured cable explains an oddity in some of the runs (L legs that didn't make sense as U would provide similar coverage).

IIRC Nuheat is now owned by Nvent which used to be Pentair which used to be Tyco. If you have any questions get used to being shunted across the planet.

We typically tested slab cables on site at 500 volts although the factory did a hipot at double voltage plus 1000. The industry standard on site tends to be 20 megohms but infinity is preferred.

If the ground fault system is doing its job, slightly off readings don't worry me. If it starts tripping the GFI, fault location with infrared is normally simple. Got a spare tile?