vr6 swap!!!!!!!!Isn't that a bit old for a vr6?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ken's Motoworks' Thoughts on Ducati

- Thread starter is it fast?

- Start date

Isn't that a bit old for a vr6?

MkII Golf never came with a VR6, and a swap wouldn't be correct for the vehicle. Ya don't hack up a Syncro just to get a VR6 in it.

Buddy had a sweet Corrado back in high school. Always wanted that when I was younger.you guys are no fun.

Relax

Well-known member

MkII Golf never came with a VR6, and a swap wouldn't be correct for the vehicle. Ya don't hack up a Syncro just to get a VR6 in it.

These guys do.

NGP Rallye Golf VR6 Turbo - New German Performance

Model: Engine/Drivetrain: Suspension: 1989 Rallye Golf European 2.9 12v VR6 JE Custom Pistons Integrated Engineering Rods C2 motorsports 8.5:1 headgasket …

www.ngpracing.com

Had one a couple years ago. After he ate all the mice & chipmunks he buggered off. Didn't hang around for the kibble.Get a barn cat. We have a house cat that loves to hunt. I let him walk through the garage and shed pretty much daily. Just the scent of him has kept my garages rodent-free in two houses now.

I understand your point.Typical GTAM thread. I wonder how you could deviate the thread from "Do not buy new Ducati" to car's rims, AWD, 4WD, and other totally unrelated topics...

My post should have made the point about the rising cost and complexity of all the extra electronic stuff on modern vehicles.

After my Tacoma episode, a similar, but simpler experience with my 1090, and my experience with a VW Golf hybrid in Portugal I'm not really "feelin' the love" for electronics or engine management systems at the moment.

The Golf was a fun to drive 6 speed but the management software was VERY buggy. At one point it displayed a big exclamation mark on the dash alerting me that we had just had a collision even though we weren't moving at the time.

TK4

Well-known member

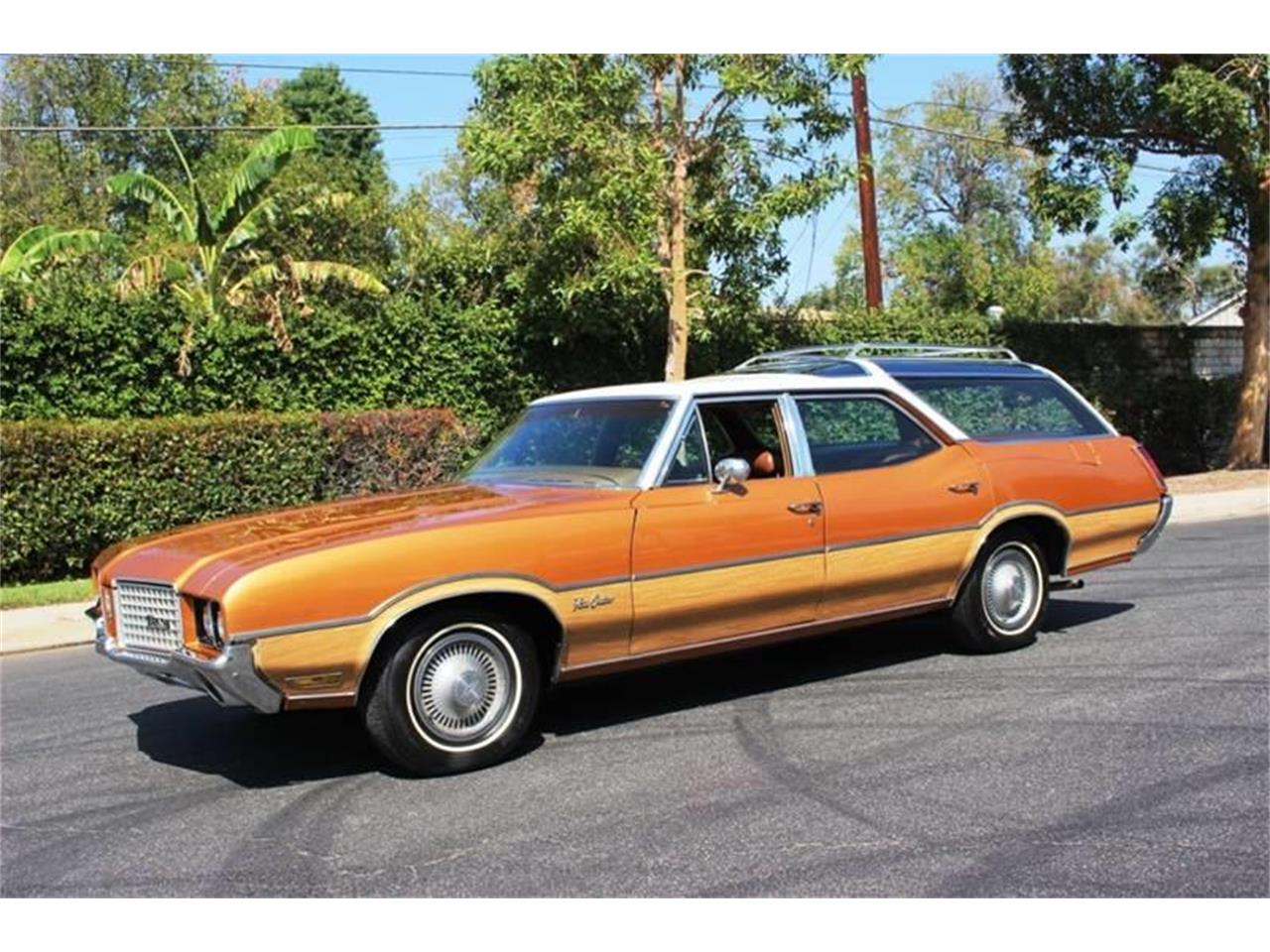

I shoulda bought one of these when I had the chance -I don’t really care much for cars, if it’s fun and affordable then everyone has one, if it’s cool and different it’s probably too exotic or too retro and therefore expensive.

I understand your point.

My post should have made the point about the rising cost and complexity of all the extra electronic stuff on modern vehicles.

After my Tacoma episode, a similar, but simpler experience with my 1090, and my experience with a VW Golf hybrid in Portugal I'm not really "feelin' the love" for electronics or engine management systems at the moment.

The Golf was a fun to drive 6 speed but the management software was VERY buggy. At one point it displayed a big exclamation mark on the dash alerting me that we had just had a collision even though we weren't moving at the time.

And yet, statistically, modern vehicles are more reliable than ever. It stinks if you're the one affected by an electronic controller that went bad, and it's annoying when the software developers do something that isn't consistent with the way you'd prefer it to be done ... but they seldom actually break nowadays. Electronic stuff usually either doesn't work straight away (because someone at the factory didn't get something put together properly) or lasts years and years.

There are a lot of different electronic controllers in modern vehicles, and they're expected to communicate with each other over a common network ... that part of it is certainly complicated, and a piece of information going over the network at the wrong time or with a corrupted signal because of who knows what can cause glitches. I know VW has been having software trouble with their vehicle electronics lately; they've gone through a few revisions. On another forum, someone who recently picked up a VW ID.4 says the complaints by the press are overstated - but they've probably got the latest revision that has (hopefully) fixed a lot of earlier complaints.

The Bolt has a commonly-reported glitch ... if you press drive or reverse too quickly after pressing "on" before it finishes doing its boot-up sequence, sometimes it will fault out "Conditions incorrect for shift" and then you have to shut it down and start over. I always wait for the "ready" indicator to come on before pushing any of the gear-selection buttons.

My almost 20 year old ZX10R has a fault in the electronics right now ... the fault-warning lamp is on most of the time. I believe the position feedback sensor in the servo motor that operates the exhaust flapper valve is worn out. (bike has 133,000 km on it) The fuel injection system itself is correctly reporting the fault. Since it doesn't cause any apparent operational problems, I'm ignoring it.

Relax

Well-known member

And yet, statistically, modern vehicles are more reliable than ever. It stinks if you're the one affected by an electronic controller that went bad, and it's annoying when the software developers do something that isn't consistent with the way you'd prefer it to be done ... but they seldom actually break nowadays. Electronic stuff usually either doesn't work straight away (because someone at the factory didn't get something put together properly) or lasts years and years.

There are a lot of different electronic controllers in modern vehicles, and they're expected to communicate with each other over a common network ... that part of it is certainly complicated, and a piece of information going over the network at the wrong time or with a corrupted signal because of who knows what can cause glitches. I know VW has been having software trouble with their vehicle electronics lately; they've gone through a few revisions. On another forum, someone who recently picked up a VW ID.4 says the complaints by the press are overstated - but they've probably got the latest revision that has (hopefully) fixed a lot of earlier complaints.

The Bolt has a commonly-reported glitch ... if you press drive or reverse too quickly after pressing "on" before it finishes doing its boot-up sequence, sometimes it will fault out "Conditions incorrect for shift" and then you have to shut it down and start over. I always wait for the "ready" indicator to come on before pushing any of the gear-selection buttons.

My almost 20 year old ZX10R has a fault in the electronics right now ... the fault-warning lamp is on most of the time. I believe the position feedback sensor in the servo motor that operates the exhaust flapper valve is worn out. (bike has 133,000 km on it) The fuel injection system itself is correctly reporting the fault. Since it doesn't cause any apparent operational problems, I'm ignoring it.

The problem isn't simply because there are so many additional electronics than before, it's two-fold (and alluded to by Ken's comments):

1. When one component dies, you need to purchase an entire assembly to replace it because everything was integrated into a single part number. I get that it's cheaper to make it all in one, but it's not like they're passing on that savings, they're just maximizing profits at the expense of serviceability. Manufacturers seem to have no incentive to make their vehicles run reliably past the warranty period.

2. Poor electronic diagnostics to easily narrow down the problem. But as mentioned, maybe Ken doesn't have all the latest tools since he presumably no longer has access to factory tools and training.

I've got a problem where the idle speed control motor is misbehaving. Sets idle properly but after riding a bit, it slowly and randomly increases idle (I've had it idling at close to 4000 RPMs at one time, which was a bit of a surprise when I let off the throttle and expected V-twin engine braking). KTM only sells the entire throttle body assembly at $1600. Meanwhile Triumph uses the same motor in their bikes and you can buy it separately, but it's still $300. For something that's supposed to make your life easier, it sure isn't. Older bikes never has this crap, just a cold start lever or button that pulled on the throttle cable a bit to up the idle speed during warm-up. They work fine and I'm considering unplugging the ISC motor and retrofitting something similar for manual control.

There seems to be no oversight on cost of parts for anything. Manufacturers now want to sell you hubs for many hundreds instead of bearings for tens of dollars, electronic control boards for any appliance are >50% of the cost of new appliance. Basically economically forcing more garbage to the dump. No reason to do any better as all competitors do the same thing. More turnover and profits for all.The problem isn't simply because there are so many additional electronics than before, it's two-fold (and alluded to by Ken's comments):

1. When one component dies, you need to purchase an entire assembly to replace it because everything was integrated into a single part number. I get that it's cheaper to make it all in one, but it's not like they're passing on that savings, they're just maximizing profits at the expense of serviceability. Manufacturers seem to have no incentive to make their vehicles run reliably past the warranty period.

2. Poor electronic diagnostics to easily narrow down the problem. But as mentioned, maybe Ken doesn't have all the latest tools since he presumably no longer has access to factory tools and training.

I've got a problem where the idle speed control motor is misbehaving. Sets idle properly but after riding a bit, it slowly and randomly increases idle (I've had it idling at close to 4000 RPMs at one time, which was a bit of a surprise when I let off the throttle and expected V-twin engine braking). KTM only sells the entire throttle body assembly at $1600. Meanwhile Triumph uses the same motor in their bikes and you can buy it separately, but it's still $300. For something that's supposed to make your life easier, it sure isn't. Older bikes never has this crap, just a cold start lever or button that pulled on the throttle cable a bit to up the idle speed during warm-up. They work fine and I'm considering unplugging the ISC motor and retrofitting something similar for manual control.

This is on your 998? As I recall, that's an older-design fuel injection system with a regular manually-operated throttle by cables, and a separate IAC motor.

The full fly-by-wire systems don't have the IAC motor at all, and the motor that operates the main throttles has had more attention paid to it in the design due to FMEA.

The full fly-by-wire systems don't have the IAC motor at all, and the motor that operates the main throttles has had more attention paid to it in the design due to FMEA.

There seems to be no oversight on cost of parts for anything. Manufacturers now want to sell you hubs for many hundreds instead of bearings for tens of dollars, electronic control boards for any appliance are >50% of the cost of new appliance. Basically economically forcing more garbage to the dump. No reason to do any better as all competitors do the same thing. More turnover and profits for all.

This is how they make you want to get a new vehicle / appliance / gadget.

I know. It's just low-hanging fruit for any politician that actually wanted to do something good for the environment. As a start, no single part for consumer goods/appliances should exceed 10% of the cost of original product. Not sure how to deal with more expensive/complicated products like motor vehicles. Similar to Oz consumer protection, if manufacturers play games to try to get around intent of the consumer protection laws, the axe falls fast and hard.This is how they make you want to get a new vehicle / appliance / gadget.

Relax

Well-known member

This is on your 998? As I recall, that's an older-design fuel injection system with a regular manually-operated throttle by cables, and a separate IAC motor.

The full fly-by-wire systems don't have the IAC motor at all, and the motor that operates the main throttles has had more attention paid to it in the design due to FMEA.

No, it's a 2010 KTM with wired throttle. My 2002 998 has no motor controlling idle. Idle is set through air bleed screws in the throttle body when the motor is warm. If that's not enough to keep it idling when cold, there's a fast idle lever that pulls on the rear butterfly for more air. Pretty dumb even for its time - the 748 and all previous 9xx models simply had a button on the throttle grip that opened the throttle a few degrees. This is what I'd ideally like to retrofit to the KTM if I decide to pocket the $300.

I agree completely.And yet, statistically, modern vehicles are more reliable than ever. It stinks if you're the one affected by an electronic controller that went bad, and it's annoying when the software developers do something that isn't consistent with the way you'd prefer it to be done ... but they seldom actually break nowadays. Electronic stuff usually either doesn't work straight away (because someone at the factory didn't get something put together properly) or lasts years and years.

There are a lot of different electronic controllers in modern vehicles, and they're expected to communicate with each other over a common network ... that part of it is certainly complicated, and a piece of information going over the network at the wrong time or with a corrupted signal because of who knows what can cause glitches. I know VW has been having software trouble with their vehicle electronics lately; they've gone through a few revisions. On another forum, someone who recently picked up a VW ID.4 says the complaints by the press are overstated - but they've probably got the latest revision that has (hopefully) fixed a lot of earlier complaints.

The Bolt has a commonly-reported glitch ... if you press drive or reverse too quickly after pressing "on" before it finishes doing its boot-up sequence, sometimes it will fault out "Conditions incorrect for shift" and then you have to shut it down and start over. I always wait for the "ready" indicator to come on before pushing any of the gear-selection buttons.

My almost 20 year old ZX10R has a fault in the electronics right now ... the fault-warning lamp is on most of the time. I believe the position feedback sensor in the servo motor that operates the exhaust flapper valve is worn out. (bike has 133,000 km on it) The fuel injection system itself is correctly reporting the fault. Since it doesn't cause any apparent operational problems, I'm ignoring it.

As I said my Tacoma has been a paragon of reliability and quality manufacture, both in components and overall. At 250,000 km it's got a ton of life left in it, and I intend to take advantage of every last km.

As GreyGhost noted, the assembly or component aspect of modern manufacturing appears to be driving up the cost of repairs. Our boiler shut off this spring because of a sensor in a manifold. According to our service guy the sensor is clearly and easily removable, but is only available as part of an assembly, which was $800 and would necessitate the near complete disassembly of the boiler to replace. Fortunately he's a great tech and a good guy working for a excellent small company. He spoke to a sales rep who had a literal basket of them. He then traced the part itself and found a source for them. The individual sensor cost $15, and they charged us for a simple 1 hr. service call.

RWD cars have two tapered wheel bearings, held on by a big nut and were/are easy to replace.There seems to be no oversight on cost of parts for anything. Manufacturers now want to sell you hubs for many hundreds instead of bearings for tens of dollars, electronic control boards for any appliance are >50% of the cost of new appliance. Basically economically forcing more garbage to the dump. No reason to do any better as all competitors do the same thing. More turnover and profits for all.

There is no easy way to replicate this on a front wheel drive car, so we get one BIG bearing, pressed into the hub... so to replace this bearing you need a decent sized press and some time.

1) your average home repair guy doesn't have decent size press

2) It is cheaper to buy a bearing/hub assembly than to pay a mechanic shop rates to putz around pressing bearings in and out.

IF you are a home mechanic with a decent sized press, no one or nothing is stopping you from buying a replacement bearing and pressing it into your old hub... just for MOST buyers it is more economical to buy a bearing/hub assembly

Relax

Well-known member

What do you consider to be a decent size? Most DIY's I've seen out there in lieu of a bench press just use threaded rod and appropriately sized cups. Impact wrench helps, though.RWD cars have two tapered wheel bearings, held on by a big nut and were/are easy to replace.

There is no easy way to replicate this on a front wheel drive car, so we get one BIG bearing, pressed into the hub... so to replace this bearing you need a decent sized press and some time.

1) your average home repair guy doesn't have decent size press

2) It is cheaper to buy a bearing/hub assembly than to pay a mechanic shop rates to putz around pressing bearings in and out.

IF you are a home mechanic with a decent sized press, no one or nothing is stopping you from buying a replacement bearing and pressing it into your old hub... just for MOST buyers it is more economical to buy a bearing/hub assembly

. I wonder how you could deviate the thread from "Do not buy new Ducati" to car's rims, AWD, 4WD, and other totally unrelated topics...

. I wonder how you could deviate the thread from "Do not buy new Ducati" to car's rims, AWD, 4WD, and other totally unrelated topics...