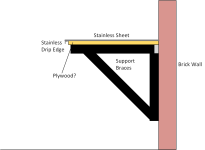

The supports will be either made from 2X or 4X outdoor capable wood or I may make them out of galvanized steel I weld together. The shape will be L with a diagonal support brace and I plan to run to within ~an inch of the edge of the countertop edge (22.5 to 23 on the top of the brace)--black in sketch. I will likely also place a strip for it to sit on at the wall all along the back (white block first sketch, may be stainless angle). The countertop will slope away from the wall for rain and I will make a drip edge along the outside out of other stainless angle.

Rough sketches, side view, top view.

Then rough idea of the corner and overall area next, really rough

View attachment 62470View attachment 62471

View attachment 62472

View attachment 62473

View attachment 62470View attachment 62471

View attachment 62472

View attachment 62473

I think I need something to run under the stainless for additional support between the braces (the plywood or what is better?) that will also cut down on the ring. Then how to bond the two together? The drip edge will be made from 304 angle as I do not have a brake to bend the 347 sheet. I also do not want any fasteners through the stainless surface. Stainless is 16 gauge (technically .063), type 347--just happen to have it.

My plumbing stack is on the other side of that basement window which I will fill in at some point (stupid spot) and I can put an outdoor sink there in the future (taking some artistic license with code) with shutoff/disconnect abilities for winter. The sink is future as I may need to do some other code work first...

Area is not covered and I do not plan on doing cabinets under the countertop now, just those supports.