The stairs that scare me are the tiny treads , the 2x8 tread stock .

Sent from my iPhone using GTAMotorcycle.com

Sent from my iPhone using GTAMotorcycle.com

A friend's place has a tight spiral. The inside turn is a vertical drop with ripples.The stairs that scare me are the tiny treads , the 2x8 tread stock .

Sent from my iPhone using GTAMotorcycle.com

Levelled out a second beam and framed in the basement to first floor support walls for the new run of half-pace stairs. 5 stairs+ double stacked landing + 5 stairs is ready to assemble. Ran into a snag when the copper water service line (which comes in under the stairs) snapped off at the ground -- lucky the water was off at the street! Gonna be chippin out basement floor concrete this morning (where's @mimico_polak ?)Working on Chez North this week.

Nothing like working on a 1920 house in the North. Woke up this morning and stepped in some bear **** when cutting the grass.

Managed to level the main beam in the basement, 1.5" variation over 24', must have moved the house jack 100 times. Bought a good Milliwakee laser level, first time not using a water tube to level a building... awesome tool.

Also took out the old 60 Amp screw in fuse panel. My service to the meter is 200A, as is the new panel. Lightning charger ready! Gas here us 2.29.

Tomorrow I cut out an old 10"run 10" rise staircase. Just laid out the replacement half-pace stringers, gotta cut them myself as the wait for stair builders is 4 months.

Couldn't you get away with a hole saw to make some room for a coupler? Or do you want to to pull a bunch of the line in case it is worn away?Levelled out a second beam and framed in the basement to first floor support walls for the new run of half-pace stairs. 5 stairs+ double stacked landing + 5 stairs is ready to assemble. Ran into a snag when the copper water service line (which comes in under the stairs) snapped off at the ground -- lucky the water was off at the street! Gonna be chippin out basement floor concrete this morning (where's @mimico_polak ?)

For some projects I wanted rough cut and it's not easy to find. Hell, I was doing a job at a mill/kiln site in northern ontario and asked if they would sell any and it was a hard no. Nothing left the site without grading and nothing can get graded without first getting planed. Good to know that the smaller guys may have some kicking around now. The quantity I needed wasn't enough to pay for a custom job.A metric crap ton of small mills opened during the lumber rush making 2x out of all sorts of softwood . And no grading stamps , which is fine for a shed , but even if your not getting an inspection it sort of makes sense to have certified wood on anything you like to stay standing.

Sent from my iPhone using GTAMotorcycle.com

A concrete hole is a great idea - never thought of that -- I usually work with tools in the bag. That's a 5lb hammer and cold chisel.Couldn't you get away with a hole saw to make some room for a coupler? Or do you want to to pull a bunch of the line in case it is worn away?

These types of surveys are useless. It's the same ones that claim people are $200-500 from bankruptcy...bankrolled by debt consolidation companies to drive business.

Stain and poly mix is usually a bad idea. It seems like it may save some effort but you give up most control, this is what happened to you.Update on my first attempt at staining wood. Applied per manufacturers instructions and used their pre-stain. Did my pantry first as it's mostly hidden anyways. Floors/shelves are a mid-grey so I chose a stain to ,match and a light coat went on black (bare pine). I ended up sanding it as best I could and applied a coat of outdoor paint I had on hand that was a better match and then sanded that twice lightly to bring back some wood grain and lighten the colour to a better match.

Second attempt was livingroom cabinet tops. First coat was a match and it looked beautiful. Stain recommendation was to do two coats so I did that second coat thinking it was for good protection and depth (stain had poly in it) which ended up being a big mistake as it made it much too dark. I'm going to try to re-stain it with just one light coat and have hit it with 150grit which has brought back some spots of almost bare wood but many dark spots remain. I'll hit it with 100grit to see if I can get it any better then stain it. Any tips on getting it lighter before staining are welcome (water based stain btw).

I was one of these people in the late 80s, first house in 86, 2 more by 90. Market crashed and lenders would not renew underwater mortgages so 2 got sold a a huge loss, wiped out all my gains and I ended up moving from an 'estate' home into a starter.

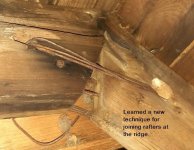

My daughter's house had 2X4 rafters 16 feet long, Bowed like ski jump.Im facinated with "old home" construction fixes and how many were done by three guys that worked at the mine and did construction on the side. And a lot befiore any municipality had a building code.

Place we bought in KW had a garage with a 15deg lean , go inside to find half the collar ties taken out and 10 ceiling joists , new nieghbour said it was done 20yrs ago so they could store stuff up top easier. Great except adding 500lbs to the top of an unstable project? brilliant

I'm replacing a 10 flight 9 rise 9 run to the second floor and a 10x8 to the basement. They are currently at opposite ends of the house, moving them on top of each other in the middle.gets me a small office and a nice hallway closet. Got super lucky -- home depot sells steel stringers, 5 stair run is $110 for the pair -- not bad considering 2X12 are $65 and I have a couple hours cutting time.The stairs that scare me are the tiny treads , the 2x8 tread stock .

Sent from my iPhone using GTAMotorcycle.com

I'm doing that now, using strongbacks.My daughter's house had 2X4 rafters 16 feet long, Bowed like ski jump.

I added a mid point beam and jacked some of the bow out of them.