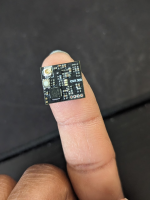

Ordered all the drone parts, now lets practice soldering until they get here

Still can't figure out what hyper cheap 4k cam i'm going to use (when you don't need a dedicated battery, those things are LIGHT!)

Hawkeye thumb 4k or runcam thumb pro v2...

Could probably make for half decent dashcams too if there's a power source somewhere

Still can't figure out what hyper cheap 4k cam i'm going to use (when you don't need a dedicated battery, those things are LIGHT!)

Hawkeye thumb 4k or runcam thumb pro v2...

Could probably make for half decent dashcams too if there's a power source somewhere

times a week , zoom cycling sessions. Both feel early but winter happens every year …..

times a week , zoom cycling sessions. Both feel early but winter happens every year …..