Relax

Well-known member

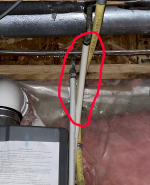

My son asked me "Is that noise coming from the basement normal?" As I near the top of the stairs, I hear the dreaded sound of splashing water and run downstairs to find water spraying out from around the tankless water heater. Turned off the input valve to the heater, and the splashing slows. After calling Reliance to come look, I go back down and dry everything off to take a closer look. I thought one of the PEX fittings came loose, but when I reopened the input valve I could see water spraying from a pinhole in one of the PEX tubes coming out of the heater. Reliance says that they need the technician to confirm whether that's covered by the water heater rental agreement, but they believe only the tank itself is, not any of the plumbing or valves.

So my first question is, what could cause a pinhole leak to develop? It's not on the side of the tube touching the wall that it's mounted to, it's shooting out the side, and about halfway between the ends of the tube. This really affects my impression of the reliability/durability of PEX compared to copper, and puts a damper on my plans to eventually replace all of my copper with PEX.

The next question is - if it's not covered by Reliance and I need to fix it myself, can I just cut the section out with a hose cutter and rejoin them with a PEX union, or do I need to replace the entire length of PEX because it's compromised, and how do I know if any other pipes will do the same soon (or later)?

So my first question is, what could cause a pinhole leak to develop? It's not on the side of the tube touching the wall that it's mounted to, it's shooting out the side, and about halfway between the ends of the tube. This really affects my impression of the reliability/durability of PEX compared to copper, and puts a damper on my plans to eventually replace all of my copper with PEX.

The next question is - if it's not covered by Reliance and I need to fix it myself, can I just cut the section out with a hose cutter and rejoin them with a PEX union, or do I need to replace the entire length of PEX because it's compromised, and how do I know if any other pipes will do the same soon (or later)?