Asking for a friend. The hot water tank has drain for the pressure relief pipe. If he bumps the tank over can he share the drain with a washing machine?

Sent from my Pixel 5 using Tapatalk

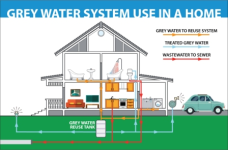

If the drain is conventional leading to a sewer system dumping washer water would be OK if it didn't overload the system. My beef with them is that floor drains are rarely used the way gramma did, draining the wringer washer onto the floor every week and keeping the trap full.

If the trap runs dry sewer gas can get into the basement. I ran a trap seal line from the sink taps that tops up the trap whenever the taps are used.