Meets the practical

'79 GS1000 with a custom big bore kit, basically the same as the Yosh 1100cc kit but with 11.5/1compression and 1mm GSXR rings.

BIG FAN of modern thin, flexible, low tension rings... friggin' impossible to install from the bottom.

The GSXR has a plain bearing bottom end, so the pistons go in from the top and you can use a ring install collar. BINGO BONGO

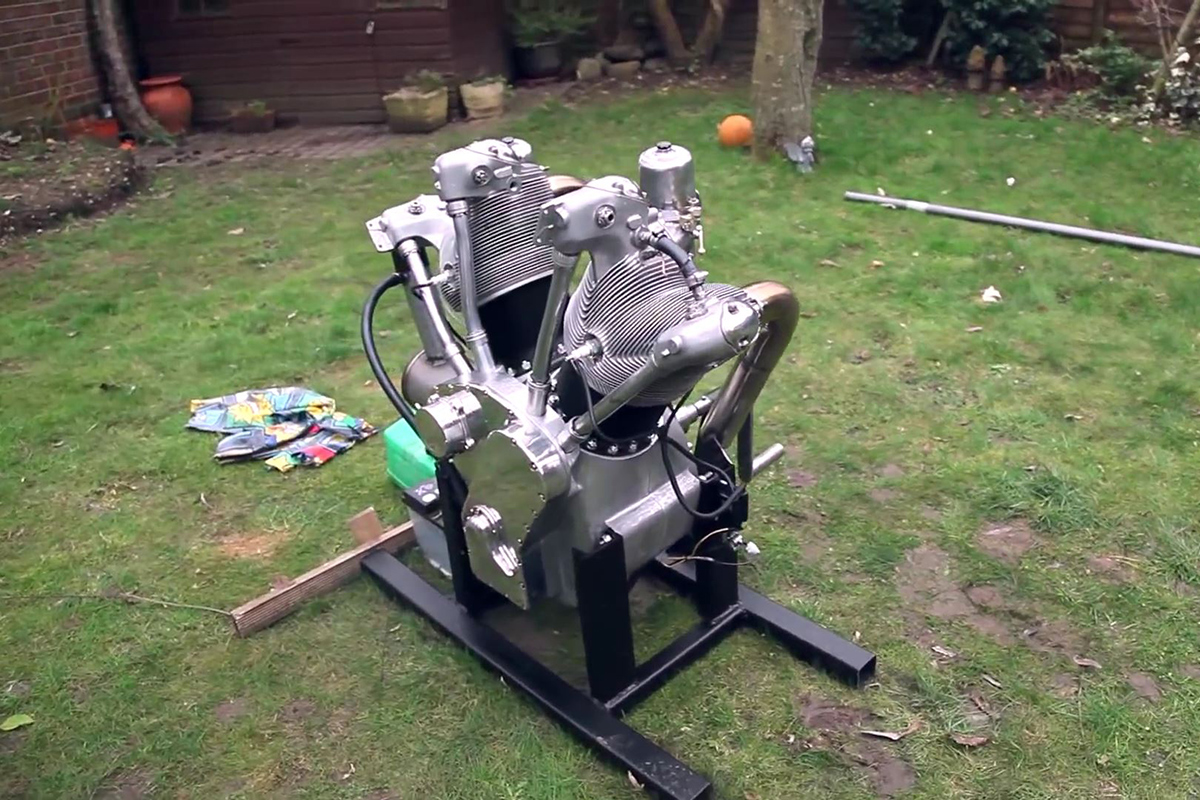

The GS has a roller bottom end so the pistons have to go in from the bottom (the rods don't come off). There's no room. The picture shown even has the 12 -10mm cylinder studs removed

I've been trying since Thursday afternoon. The last time I did this it took three of us all day... I'm alone this time

YEEEeeeeeHAAAaaaaa

'79 GS1000 with a custom big bore kit, basically the same as the Yosh 1100cc kit but with 11.5/1compression and 1mm GSXR rings.

BIG FAN of modern thin, flexible, low tension rings... friggin' impossible to install from the bottom.

The GSXR has a plain bearing bottom end, so the pistons go in from the top and you can use a ring install collar. BINGO BONGO

The GS has a roller bottom end so the pistons have to go in from the bottom (the rods don't come off). There's no room. The picture shown even has the 12 -10mm cylinder studs removed

I've been trying since Thursday afternoon. The last time I did this it took three of us all day... I'm alone this time

YEEEeeeeeHAAAaaaaa