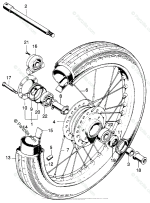

Front wheel 1972 CB750:

Heated one side of the hub, greased the bearing and tapped it into the hub. Felt it hit bottom and gave it a couple more shots to be sure. Was driving it with a large socket that only connected the outer race. While it was warm I greased the slotted aluminum adjustment/locking collar and spun it in. Used a blunt punch to tap it home and then a couple more taps.

Flipped the wheel, slid the axle in from one side, used it to center the weird 3 pronged bearing spacer with the next bearing. Then drove the second bearing in. (first side went so easily I didn't heat the other side - it did not take much effort to drive the second bearing in)

Felt the second bearing "meet" the spacer and gave it a few more taps to be sure.

Everything looks fine, EXCEPT now it's real bugger to get the axle in. It will only go all the way with a tap from a rubber mallet. From each side I can slide the axle in past the first bearing and into the spacer but then I hang up on the second bearing. Again I can do that from either side.

Tried a second axle thinking maybe it was bent a bit but it hangs up too.

All I can think is one bearing is slightly cocked.

Thoughts or suggestions??

Heated one side of the hub, greased the bearing and tapped it into the hub. Felt it hit bottom and gave it a couple more shots to be sure. Was driving it with a large socket that only connected the outer race. While it was warm I greased the slotted aluminum adjustment/locking collar and spun it in. Used a blunt punch to tap it home and then a couple more taps.

Flipped the wheel, slid the axle in from one side, used it to center the weird 3 pronged bearing spacer with the next bearing. Then drove the second bearing in. (first side went so easily I didn't heat the other side - it did not take much effort to drive the second bearing in)

Felt the second bearing "meet" the spacer and gave it a few more taps to be sure.

Everything looks fine, EXCEPT now it's real bugger to get the axle in. It will only go all the way with a tap from a rubber mallet. From each side I can slide the axle in past the first bearing and into the spacer but then I hang up on the second bearing. Again I can do that from either side.

Tried a second axle thinking maybe it was bent a bit but it hangs up too.

All I can think is one bearing is slightly cocked.

Thoughts or suggestions??