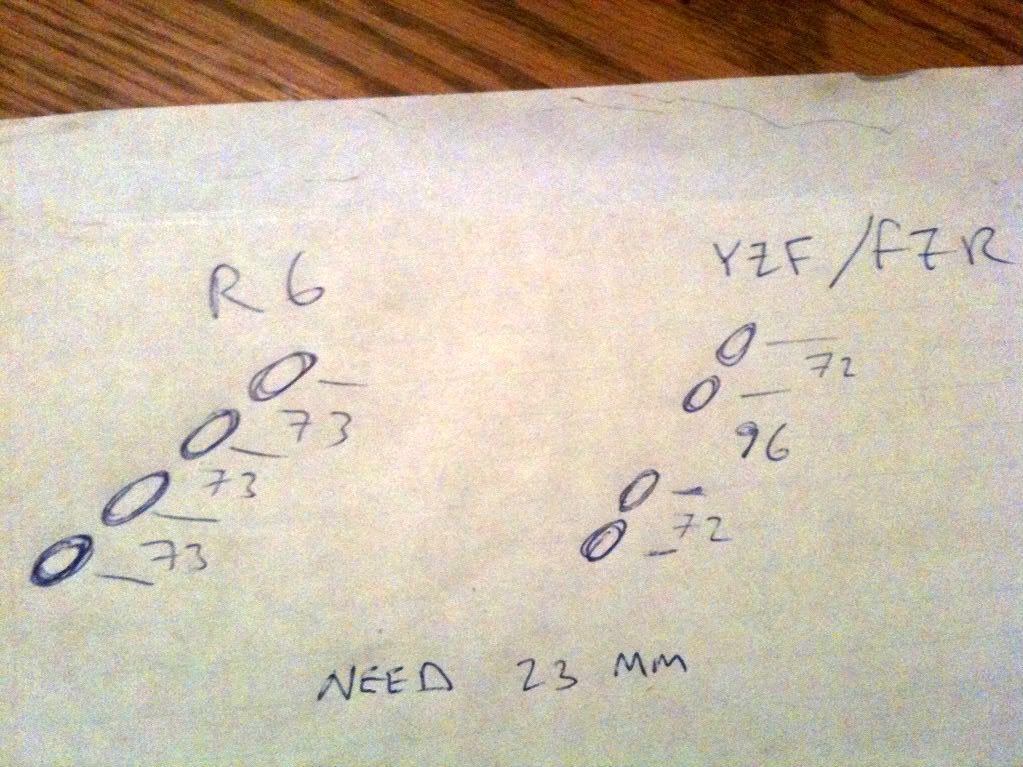

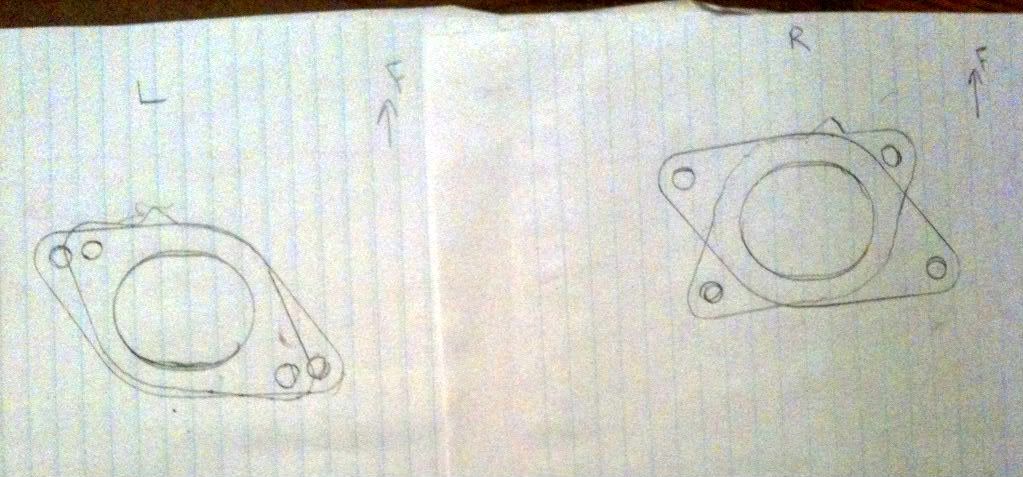

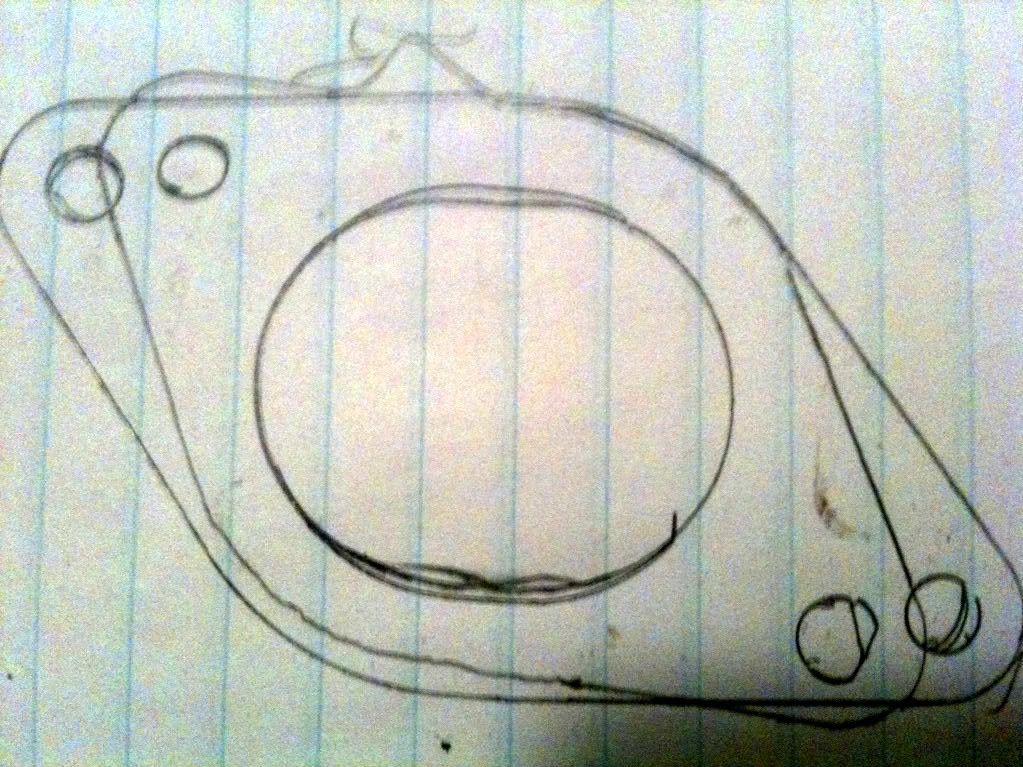

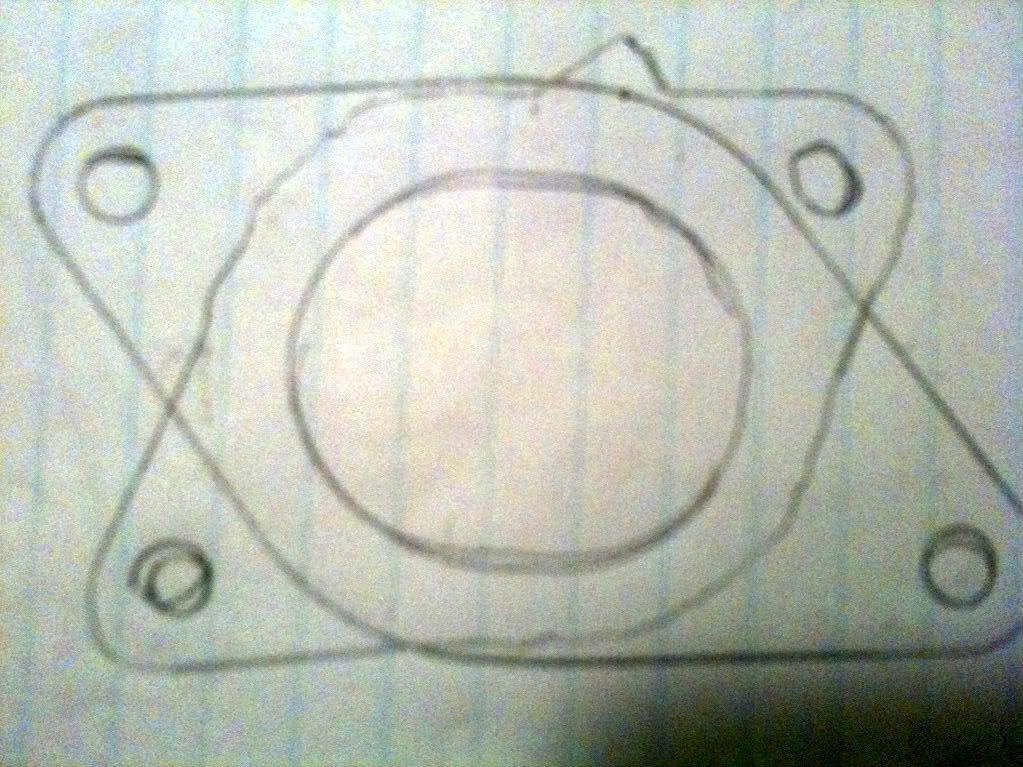

If I'm understanding this correctly, you need some plates with one set of counterbored holes that can be screwed down to the FZR cylinder head, but which have tapped holes in the correct orientation for the throttle body holders? In the one drawing, make sure the tapped holes aren't going to interfere with the counterbores - looks very close.

It won't be any easier to make these out of Plexiglas than to just go straight to aluminum. Just make sure your drawing is accurate.

Are the R6 throttle body holders sensitive to orientation? Some of them have a notch to clear the spray pattern from the injector, but if they don't, it might be possible to re-orient them to a different angle if the hole pattern is trouble.