Since this thread has moved onto welding, I have a mobile welder coming out tomorrow to repair a broken hinge on my driveway gate, I'll be interested to see his setup.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blacksmithing Anyone?

- Thread starter Jampy00

- Start date

Really high probability that they have an engine driven stick welder in the bed. Great setup for mobile work.Since this thread has moved onto welding, I have a mobile welder coming out tomorrow to repair a broken hinge on my driveway gate, I'll be interested to see his setup.

Do the welders double as a generator if needed?Really high probability that they have an engine driven stick welder in the bed. Great setup for mobile work.

I haven't looked at newer ones. Older ones were also generators.Do the welders double as a generator if needed?

PM sentThanks for the steel suggestions folks and Amazon for looking into it .

Sent from my iPhone using GTAMotorcycle.com

I don't know if a scrap yard would cut the pieces.You're about 19.5lbs/ft -- A steel jobber will be in the $20/pc range (about a buck a pound) for cut pieces. A steel retail store will be about $50/pc, or about 2.50/lb.

A scrap yard might have what you need for $0.50/lb.

In high school machine shop a detention was served making square washers. The teacher clamped a piece of 2X2 steel bar in a vice and gave you a hacksaw with a dull blade. Make a washer. If you break the saw blade you get another dull one and you start new cut. It did wonderful things for my memory, like remembering my homework.

It inspired me to get an 18V Milwaukee steel cutting circular saw because there's no way I'm ever doing the hacksaw thing again.

They branched off from Metal Supermarkets years ago and I go to them for my oddball projects. If the project is conceptual I wander through their offcuts and design around the pieces I find. Good people.McKinnon Metals in Vaughan is my go to place for metals. Great service, very fair prices on small orders.

Their service and pricing on cutting is also top notch.

I built some cages to hold / protect some equipment at work using 3/4" 0.125" wall square tubing. Nothing too fancy, just some rectangular frames ~3'Wx4'Lx3'H give or take with a bunch of cross bracing.

Made the first one as a prototype using 8' stock from Metal Supermarkets. Ended up with 56 pieces to make up 1 unit. Almost all of the braces are mitered on at least one if not both ends. Used over 60' of tubing for the first one and spent a lot of time at the chop saw.

Ordered materials from McKinnon Metals for 7 more cages. I was smart and sent them a cut sheet now that I had a final design.

That order for material for 7 units with 392 cuts cost as much as just bulk material for 2 units from Metals Supermarket.

Order was ready for pick up in less than 24 hours and it was great, not just good.

Cuts were clean and sharp. Edges had been dressed with some care. Lengths and angles were all spot on. This was easy to see as the order was neatly bundled by dimension and all the edges look like they were cut at the same time with a giant sword. Each bundle was clearly labeled.

Care was taken in every step of the operation. This was not a very valuable order to them, but they knocked it out of the park instead of just giving it to the shop dummy to hammer out quickly as possible.

Have I mentioned cheap yet?

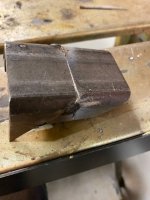

I got messing around in the garage yesterday.Hmm can anyone buy a welder? Curious what you have? I've a couple of things I'd like to weld. I wouldn't get a lot of use out of it but it's something that's not to expensive.

Photo 3 is the 120 volt welder and 1/16" & 3/32" 6013 rods

Photo 2 shows it doing a decent job of tacking (IMO) 3/16" material. If I was doing something structural I could then take the assembly to a weld shop and have them do things right.

Photo 1 is some typical newbie welds with 1/16" rods and 16 gauge mild steel @ 40 amps. Weld puke but if a person can get a half inch of decent weld it shows the capability of the machine. Skills take time to develop. The welds go from not enough penetration, ugly but they work and burn through. All skill related.

The welder would work fine for the 16 gauge if I had more skill.

The welder lists at ~$230 at CTC but comes on sale regularly for a big chunk off. A decent starter helmet is in the same price range.

Striking an arc reminds me of a person learning to drive manual on a vehicle with a manual transmission and small engine. Getting the feather point isn't easy for the newbie. This welder is similar.

A more powerful welder would be like learning manual on a vehicle with a big block V-8 diesel. The mass of the engine and its torque launches the truck.

Keep in mind that stick welders are basically transformers that trade volts and amps. A 120 volt welder drawing 20 amps can only produce 2400 watts. At 75 amps that means 32 volts open circuit and arcs are harder to strike.

A non welding teacher friend was subbing for the weld shop teacher for a short while and noticed the kids burning away half the rod on scrap before doing the stuff that would be marked. A short rod is easier to control and resulted in better welds and marks.

The non welding teacher asked why they didn't just cut the rods in half. It works for the newbie.

If there is slag you drag (ie don't push). Looks to me like maybe some welds were dragged and others pushed? Can't be sure from the pics, just looks like it.

AC only on the cheap welders also doesn't make your life easier. There have been very few times when I chose to weld with AC when DC was available.I got messing around in the garage yesterday.

Photo 3 is the 120 volt welder and 1/16" & 3/32" 6013 rods

Photo 2 shows it doing a decent job of tacking (IMO) 3/16" material. If I was doing something structural I could then take the assembly to a weld shop and have them do things right.

Photo 1 is some typical newbie welds with 1/16" rods and 16 gauge mild steel @ 40 amps. Weld puke but if a person can get a half inch of decent weld it shows the capability of the machine. Skills take time to develop. The welds go from not enough penetration, ugly but they work and burn through. All skill related.

The welder would work fine for the 16 gauge if I had more skill.

The welder lists at ~$230 at CTC but comes on sale regularly for a big chunk off. A decent starter helmet is in the same price range.

Striking an arc reminds me of a person learning to drive manual on a vehicle with a manual transmission and small engine. Getting the feather point isn't easy for the newbie. This welder is similar.

A more powerful welder would be like learning manual on a vehicle with a big block V-8 diesel. The mass of the engine and its torque launches the truck.

Keep in mind that stick welders are basically transformers that trade volts and amps. A 120 volt welder drawing 20 amps can only produce 2400 watts. At 75 amps that means 32 volts open circuit and arcs are harder to strike.

A non welding teacher friend was subbing for the weld shop teacher for a short while and noticed the kids burning away half the rod on scrap before doing the stuff that would be marked. A short rod is easier to control and resulted in better welds and marks.

The non welding teacher asked why they didn't just cut the rods in half. It works for the newbie.View attachment 66813View attachment 66812View attachment 66811

Had a nice little setup in a trailer. Used a generator to power the welder, it was a small one but worked just fine. It was a bigger job than we originally thought, but in the end he did an excellent job. It really inspired me to learn how to weld myself, as I have a fabrication project I've been thinking about creating, if it works could be a useful tool for small properties/farms.Really high probability that they have an engine driven stick welder in the bed. Great setup for mobile work.

While most of this thread has been the cheaper end of welders, you can get some small welders that are absolute champs if you pay more.Had a nice little setup in a trailer. Used a generator to power the welder, it was a small one but worked just fine. It was a bigger job than we originally thought, but in the end he did an excellent job. It really inspired me to learn how to weld myself, as I have a fabrication project I've been thinking about creating, if it works could be a useful tool for small properties/farms.

Weldingtipsandtricks on youtube is very good. This Old Tony is great for tig but you should start with wire/stick.

Yeah, I didn't follow the arrows and went like a drunk chasing a cat.If there is slag you drag (ie don't push). Looks to me like maybe some welds were dragged and others pushed? Can't be sure from the pics, just looks like it.

Before I got the MIG I was used to stick and feeding in the rod. When I went MIG I had to remind myself to keep the distance constant. Now messing around I have to remember to move the rod in.

I need to burn off some rods, after cutting them in half.

Watch out for the Chinese stuff. While a lot of brands look the same with a different label or colour the inner parts may be different.While most of this thread has been the cheaper end of welders, you can get some small welders that are absolute champs if you pay more.

Weldingtipsandtricks on youtube is very good. This Old Tony is great for tig but you should start with wire/stick.

The Mini Lathes all look the same but I suspect that may be the result of one foundry casting all the casings. Then they go to different companies for completion. Some use better bearings and motors so while the machines look the same they don't perform the same.

Yeah, I don't look for cheap I look for value. When I am getting closer to being prepared to purchase it'll be a lot of research before I open my wallet.While most of this thread has been the cheaper end of welders, you can get some small welders that are absolute champs if you pay more.

Weldingtipsandtricks on youtube is very good. This Old Tony is great for tig but you should start with wire/stick.