Subsequent to this ... I had *another* issue with the PC5 false-triggering in the last SOAR round, which was all rain on Sunday, despite the two wires from the quickshifter being taped over.

The orientation of the PC5 control box in the bike has those wires coming in from the back of the box, which is higher than the front, which leads to those wires being "downhill" towards the box, which led to water running down the wire and into the box underneath the piece of tape above them ...

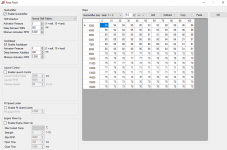

But this time, I recognised the problem when it developed, and the quick-fix at the track was to set the minimum quickshift RPM to 500 rpm below the normal shift RPM ... that way, it could false-trigger all it wanted mid-corner below that RPM and it wouldn't do anything, and I could deal with the occasional hiccup in the half second it spent in that 500 rpm window (only happened a couple of times).

The more permanent fix (after drying everything out!) was re-routing the cable so that it came towards the box from underneath with the wires bent 90 degrees right at the spot where they go into the box, and tape over that, so that there is no longer any water-running-downhill path for water to get in there.

It's still a crap design. Obviously they are using high-impedance inputs that are sensitive to even the slightest (micro-amperes?) leakage to ground. I know their circuit works by biasing the input wire high and then detecting whether the switch shorts it to ground, but if water intrusion leaks enough current to trip the sensor, it's too sensitive. And they should really be using weathertight connections - not bare wire ends inserted into a terminal strip and held by a set-screw.

Dunno about the others but the Kawasaki OEM shift-rod sensor is actually a strain gauge, not just an on-off switch. It's actually measuring how much force you are applying and in which direction. I'm not privy to their programming but it wouldn't surprise me if they are not using a "dumb timer" (like how the aftermarket ones operate) but rather are watching engine RPM and gear-position switch, and are cutting ignition until they see gear-position change and engine RPM drop to confirm that the shift is complete and then re-activating ignition at that moment. The ECU knows RPM, shift-rod force, which gear is currently selected, whether you are using the clutch, etc.

The orientation of the PC5 control box in the bike has those wires coming in from the back of the box, which is higher than the front, which leads to those wires being "downhill" towards the box, which led to water running down the wire and into the box underneath the piece of tape above them ...

But this time, I recognised the problem when it developed, and the quick-fix at the track was to set the minimum quickshift RPM to 500 rpm below the normal shift RPM ... that way, it could false-trigger all it wanted mid-corner below that RPM and it wouldn't do anything, and I could deal with the occasional hiccup in the half second it spent in that 500 rpm window (only happened a couple of times).

The more permanent fix (after drying everything out!) was re-routing the cable so that it came towards the box from underneath with the wires bent 90 degrees right at the spot where they go into the box, and tape over that, so that there is no longer any water-running-downhill path for water to get in there.

It's still a crap design. Obviously they are using high-impedance inputs that are sensitive to even the slightest (micro-amperes?) leakage to ground. I know their circuit works by biasing the input wire high and then detecting whether the switch shorts it to ground, but if water intrusion leaks enough current to trip the sensor, it's too sensitive. And they should really be using weathertight connections - not bare wire ends inserted into a terminal strip and held by a set-screw.

Dunno about the others but the Kawasaki OEM shift-rod sensor is actually a strain gauge, not just an on-off switch. It's actually measuring how much force you are applying and in which direction. I'm not privy to their programming but it wouldn't surprise me if they are not using a "dumb timer" (like how the aftermarket ones operate) but rather are watching engine RPM and gear-position switch, and are cutting ignition until they see gear-position change and engine RPM drop to confirm that the shift is complete and then re-activating ignition at that moment. The ECU knows RPM, shift-rod force, which gear is currently selected, whether you are using the clutch, etc.