|

|

|

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Adding variable speed to a tool.

- Thread starter nobbie48

- Start date

Depends if it is a standardize motor. If so you just need a new 3 phase motor and a vfd.I was thinking of changing my small single phase milling machine motor (1 HP 240 Volt) to a variable speed. Is this a plug and play or more complex?

It would make speed changes simpler than messing with pulleys and belts.

Sent from my KFONWI using Tapatalk

Definitely 100% maybe

www.orientalmotor.com

www.orientalmotor.com

I read a bit, it looks like what you want to know.

There is a few different ways, but I think you always lose efficiency

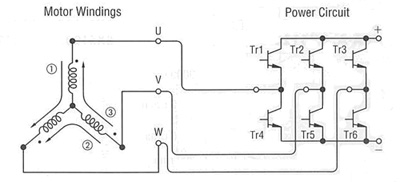

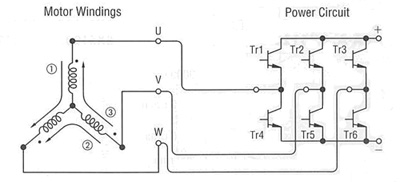

Speed Control Methods of Various Types of Speed Control Motors

A large number of motors are being used for general purposes in our surroundings from house-hold equipment to machine tools in industrial facilities. The electric motor is now a necessary and indispensable source of power in many industries. The function and the performance required for these...

I read a bit, it looks like what you want to know.

There is a few different ways, but I think you always lose efficiency

You don't even need three phase motor for VFD. It's not hard. Price is highly variable. Do you take your chance with Aliexpress (no english manual)VFD or do you buy a proper commercial unit? Huge price difference.

A variac might work, but I wouldn't do it for that type of load now that VFD's are not horrendously expensive.

A variac might work, but I wouldn't do it for that type of load now that VFD's are not horrendously expensive.

Depends if it is a standardize motor. If so you just need a new 3 phase motor and a vfd.

This is the way to do it. If it's a mill you may need a C or D or C to D flange adapter, but a 3 phase motor and a VFD is the way to go.

The VFD can be powered from Single phase, usually it is a matter of oversizing the VFD in the 75 ~ 100% range. There are VFDs designed for this purpose and have two out of 3 inputs designated for a single phase application.

There is nothing like adjusting your cutter speed on the fly by simply turning a knob.

There are single phase VFDs out there, but they're primarily for start-up control. Current limiting, ramped start. Air Conditioning and Refrigerators are common uses for this. VFDs for continuous speed control is not practical on a single phase motor. Pretty much all common single phase motors have a start winding that is powered and wound out of phase with the primary winding to provide torque and rotation direction from stopped. The start winding cannot be run continuously and once the motor is near synchronous speed, the power to winding is turned off.

You don't even need three phase motor for VFD. It's not hard. Price is highly variable. Do you take your chance with Aliexpress (no english manual)VFD or do you buy a proper commercial unit? Huge price difference.

A variac might work, but I wouldn't do it for that type of load now that VFD's are not horrendously expensive.

I don't know that much about the subject but don't like the variac idea as under voltage can be harder on a motor than a bit of over voltage. The same motor will only run weaker but still want to turn the same speed. My simplest concept would be the equivalent of a variable speed drill.

I have a 10 amp variac which wouldn't be enough and I've had cheap MIC ones that are a fraction the price and a fraction the quality.

There are some undocumented combinations on line for a few hundred dollars but a lot of bargains have an Achilles heel. One switching error and circuits pop.

This is the way to do it. If it's a mill you may need a C or D or C to D flange adapter, but a 3 phase motor and a VFD is the way to go.

The VFD can be powered from Single phase, usually it is a matter of oversizing the VFD in the 75 ~ 100% range. There are VFDs designed for this purpose and have two out of 3 inputs designated for a single phase application.

There is nothing like adjusting your cutter speed on the fly by simply turning a knob.

There are single phase VFDs out there, but they're primarily for start-up control. Current limiting, ramped start. Air Conditioning and Refrigerators are common uses for this. VFDs for continuous speed control is not practical on a single phase motor. Pretty much all common single phase motors have a start winding that is powered and wound out of phase with the primary winding to provide torque and rotation direction from stopped. The start winding cannot be run continuously and once the motor is near synchronous speed, the power to winding is turned off.

The present motor runs a vee belt so the simplest conversion would be not changing that as it would require major bracket work. Any idea of the costs for a motor and VFD to match the existing 1 HP one?

We did a milling machine some years ago that had a 3/4 or 1 hp motor, I don't remember. We had the motor rewound for 3 phase, I think in the 3 or 4 hundred $ range and found an Allen Bradley 2 HP VFD used somewhere for $ 100. The old VFD was quite a bit larger than they are today, but it had a remote control for Forward/Off/Reverse and a speed control knob. We mounted it in the same location as the original motor switch.

Have a look at the plate on your motor. Find the "frame" and check the internet for three phase motors of the same frame. If that doesn't work, find out what flange and shaft size you have and see if there is a compatible 3 phase motor. If all that fails, talk to a motor shop.

Have a look at the plate on your motor. Find the "frame" and check the internet for three phase motors of the same frame. If that doesn't work, find out what flange and shaft size you have and see if there is a compatible 3 phase motor. If all that fails, talk to a motor shop.

|

|

|

|

|