thirstforspeed

Well-known member

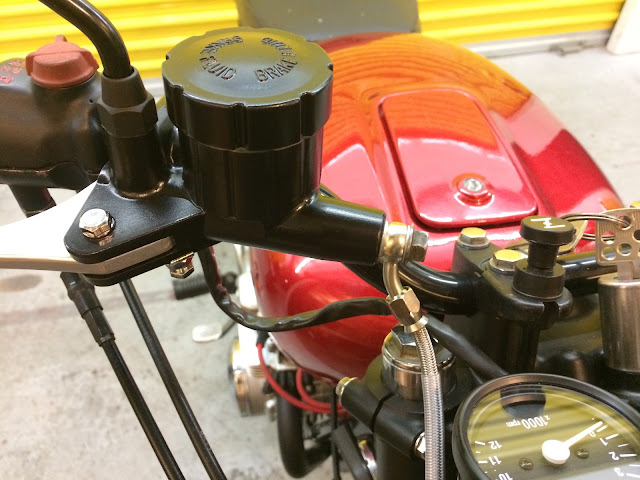

Just a quick update. I have ran into problems bleeding my front brake. (if you have trouble bleeding the rear, your problems are bigger than you think, haha  )

)

Anyway, the MC was not allowing fluid into the lines. The MC was professionally rebuilt, but I think that the rebuild kit was not the correct one, because the little tiny hole in the reservoir was blocked by metal. So, there was no fluid getting into the piston area, and hence I was not able to bleed the brakes.

In an effort to ride the damn thing, I just broke down and bought a new MC assembly from Sirius Consolidated so that I can just get on with it. Should be here by the weekend so I can give it another try. Once I get the brakes bled, I will confirm what the problem was on the OE MC, but I am almost certain the rebuild kit was incorrect. Oh well, **** happens, minor setback.

Other than that, the only outstanding items are to loctite all the front end parts and put the chain on. And maybe fix carb #2, which I think has a stuck float. All the electrical is done, and other than the float thing, runs great.

Should be on the road in a week or so. famous last words.

Anyway, the MC was not allowing fluid into the lines. The MC was professionally rebuilt, but I think that the rebuild kit was not the correct one, because the little tiny hole in the reservoir was blocked by metal. So, there was no fluid getting into the piston area, and hence I was not able to bleed the brakes.

In an effort to ride the damn thing, I just broke down and bought a new MC assembly from Sirius Consolidated so that I can just get on with it. Should be here by the weekend so I can give it another try. Once I get the brakes bled, I will confirm what the problem was on the OE MC, but I am almost certain the rebuild kit was incorrect. Oh well, **** happens, minor setback.

Other than that, the only outstanding items are to loctite all the front end parts and put the chain on. And maybe fix carb #2, which I think has a stuck float. All the electrical is done, and other than the float thing, runs great.

Should be on the road in a week or so. famous last words.